How Miniature High-Voltage Supply Modules Are Tested

- Ryan Saldana

- Sep 10, 2025

- 5 min read

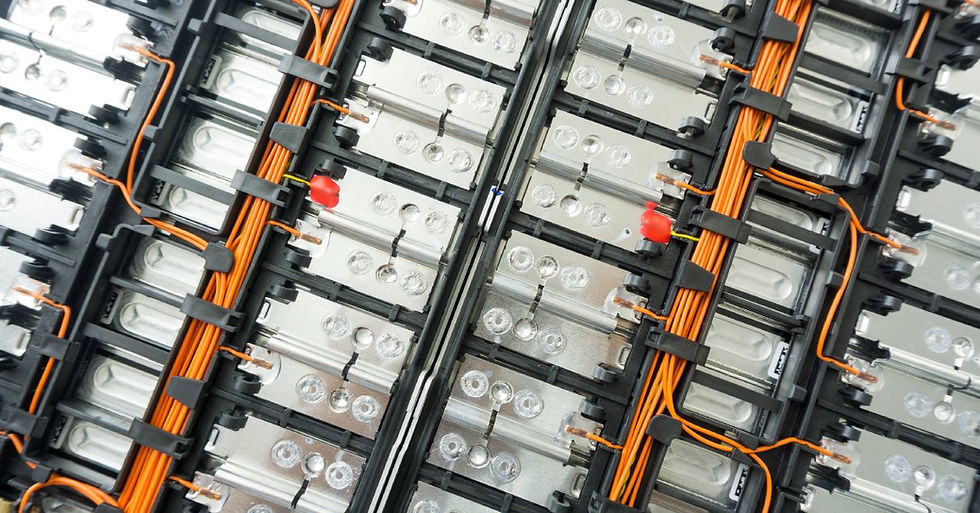

Miniature high-voltage supply modules are compact devices that can transform low voltages into outputs ranging from tens to thousands of volts. Their small size and ability to deliver precise outputs in demanding environments make them valuable for innovation. To ensure that these systems remain compliant and perform reliably, operators in high-stakes industries must test miniature high-voltage supply modules rigorously.

A single flaw could lead to severe consequences, from device malfunctions to safety hazards. By understanding what goes into testing these modules, you’ll gain valuable insights into the precision and care required to produce reliable, high-voltage solutions.

The Importance of Testing Miniature High-Voltage Supply Modules

Testing miniature high-voltage supply modules determines if these products meet the rigorous demands of the industries they support. These devices deliver precision in advanced technologies, yet flaws during production or usage can pose risks for operators. By conducting thorough evaluations, manufacturers can guarantee that each module adheres to stringent standards for performance, safety, and durability.

Ensuring Safety Through Rigorous Testing

Prioritizing safety reduces the chance of operator errors in high-voltage systems, as even minor errors can result in electrical hazards. By running tests such as insulation checks and high-pot testing, manufacturers can address potential risks and identify weaknesses that may lead to real-world hazards. In applications where lives depend on system integrity, such as medical imaging, these safety measures uphold compliance with regulatory standards and protect operators from harm.

Guaranteeing Reliability and Long-Term Performance

Systems such as particle accelerators or aerospace instruments depend on a steady and consistent power supply. Testing for parameters such as load regulation and endurance proves whether modules can sustain performance over time and under varying operational conditions.

Detecting complications such as voltage instability through controlled evaluations prevents malfunctions that might disrupt operations. Comprehensive testing builds confidence in these technologies to perform in the high-stakes environments they are suitable for.

Common Testing Methods for High-Voltage Supply Modules

To determine the performance and safety of miniature high-voltage supply modules, operators rely on a diverse range of testing methods. Each test verifies how well these modules function under various conditions.

EMI/EMC Testing

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) testing check a module’s ability to perform reliably in the presence of electromagnetic disturbances. EMI testing identifies whether the module generates interference that could disrupt other systems, while EMC testing determines if the module itself resists external interference. These tests check for stable operation in electronic systems, particularly in sensitive fields such as medical technology and communications.

Insulation Resistance Testing

Insulation resistance testing evaluates the quality of the insulation materials within the module. These materials prevent current leakage, which could lead to malfunctions or safety hazards. By applying a high voltage over a set period and measuring the resistance, this method checks if the insulation can effectively handle the intended operational stresses.

High-Pot Testing

High-pot testing, also known as high-potential or dielectric withstand testing, identifies weaknesses in a module’s electrical insulation. This test applies a voltage higher than normal operating levels to verify that the system can endure peak stress without breaking down. An untested module might fail under pressure, so high-pot testing inspects the reliability of these devices when subjected to demanding conditions.

Load Regulation Testing

Load regulation testing measures how well a module maintains a stable output voltage despite varying load conditions. This stability works best in applications such as medical devices or research tools, where even slight voltage fluctuations can disrupt functionality. Simulating different loads allows the module to deliver consistent performance.

Endurance Testing

Endurance testing analyzes how a module performs under prolonged operational conditions. By exposing the module to sustained electrical stress over extended periods, this method reveals any weaknesses that might not be apparent during shorter tests.

The goal is to assess whether the module can handle continuous usage without degradation. Industries relying on these modules for long-term applications, such as telecommunications, benefit from stable and durable components free from premature failure.

Temperature Cycling Testing

Temperature cycling testing evaluates how well a module withstands extreme temperature variations. This test repeatedly exposes the module to high and low temperature limits to mimic real-world environmental changes.

Rapid shifts in temperature can cause internal components to expand or contract, which leads to potential damage or malfunction. Modules that pass this testing demonstrate their reliability in environments with fluctuating thermal conditions, such as aerospace or outdoor installations.

Short-Circuit Testing

Short-circuit testing confirms that a module can handle unexpected electrical faults without catastrophic failure. Through a short-circuit simulation, manufacturers verify whether the system’s protective mechanisms, such as fuses or shutdown capacities, function as intended. This prevents damage to connected devices and reduces safety risks for operators.

Safety Considerations for Miniature High-Voltage Supply Modules

Implementing proactive measures and thorough safety protocols allows these devices to perform reliably while reducing risks in even the most demanding environments. By addressing safety considerations, industries can maintain compliance and protect both personnel and equipment.

Operator Training

Train staff in high-voltage power supplies to reduce the likelihood of errors when handling these systems. Operators must understand the potential hazards and follow established procedures to mitigate risks. A well-trained team maintains a safe work environment and prevents costly or harmful mistakes.

Equipment Maintenance

Proactive upkeep supports consistent performance while minimizing failures and operational disruptions. Schedule regular maintenance on high-voltage supply modules to detect signs of wear, corrosion, or other issues that might compromise safety.

Protective Shielding

Protective shielding prevents operators from being exposed to high voltage. Using enclosures, barriers, or insulation material adds an extra layer of defense against electrical hazards. Implement these shields during system testing and repairs for a safe workplace environment.

Compliance With Regulations

Strict adherence to industry standards and regulations prevents safety oversights. Guidelines such as IEC 61010 or UL standards outline requirements for safe operation and design. Compliance demonstrates a commitment to safety for your business.

Technology Enhancing Testing Processes

Advancements in technology have significantly improved the efficiency and precision of testing processes for miniature high-voltage supply modules. Modern automated testing systems accelerate diagnostics and minimize human error. These systems can perform complex evaluations, such as high-pot and load regulation testing, with greater speed and consistency.

Innovative tools such as thermal imaging cameras and advanced sensors also offer new ways to monitor module performance under various conditions. These technologies identify subtle issues, such as thermal hotspots or insulation weaknesses, that might otherwise go unnoticed in traditional testing. By integrating cutting-edge technology, industries can meet higher safety standards and achieve superior quality control in their high-voltage systems.

Investing in reliable equipment ensures your systems remain efficient and durable over time. HVM Technology specializes in high-voltage power supply modules engineered for compact systems and rigorous demands. Explore our innovative miniature high-voltage solutions today, and elevate your operations with trusted performance.

Comments